Leading Lift Companies in London: Offering Top Quality Installations and Upkeep

Leading Lift Companies in London: Offering Top Quality Installations and Upkeep

Blog Article

Checking Out the Diverse Selections of Lift Solutions and Their Common Breakdowns

In the world of upright transportation, lift systems play a critical duty in assisting in the motion of individuals and goods across numerous structures. From hydraulic to traction, pneumatically-driven, and chairlift systems, each kind boasts its unique design and operational characteristics. Nonetheless, similar to any kind of mechanical system, lift systems are at risk to breakdowns that can range from minor troubles to important failings. Understanding the diverse ranges of lift systems and their regular malfunctions offers important insights into making certain the safety and security and performance of vertical transportation.

Elevator Solutions Introduction

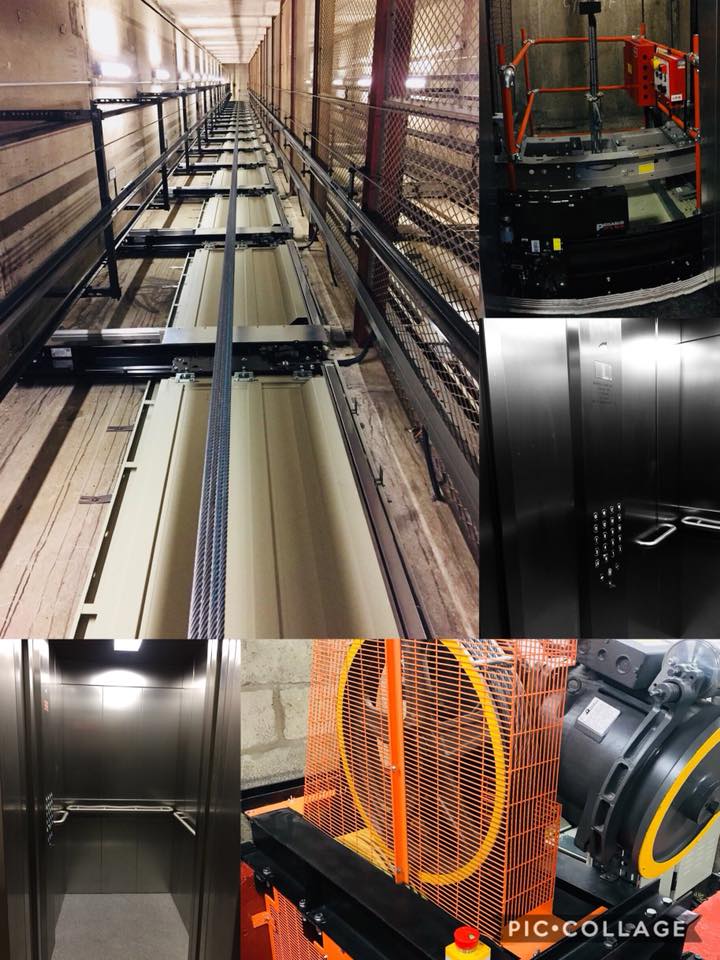

One basic element of modern metropolitan facilities is the lift system, vital for upright transport in buildings of varying heights. Elevators, also referred to as lifts in some areas, are made to effectively relocate individuals and products between different floorings within a building. These systems contain different vital elements, including the elevator auto, raising mechanism, control, and weight systems.

The lift automobile acts as the system that brings passengers or cargo, while the hoisting device, generally made up of chains or ropes, moves the automobile up and down along the lift shaft. The counterweight helps balance the lots of the vehicle, making the system much more energy-efficient - lift maintenance contractors. Control systems, such as switches inside the car and on each floor, permit customers to choose their desired destination and run the elevator safely

Hydraulic Lift Equipments

Relocating from the realm of lift systems introduction to a much more specific domain name, hydraulic lift systems use a distinctive technique to vertical transportation within buildings. These systems are generally discovered in reduced to mid-rise buildings where the vertical traveling distance is moderate.

One common malfunction of hydraulic lift systems is oil leakage as a result of damaged seals or harmed hydraulic hoses. This can bring about a decline in system effectiveness and potentially concession security if not without delay addressed. One more typical problem is valve problems, which can cause the lift not stopping at the proper degree or experiencing jerky activities during operation. Routine maintenance and hydraulic fluid checks can aid avoid these breakdowns and guarantee the smooth procedure of hydraulic lift systems.

Traction Lift Equipments

Checking out the detailed mechanisms of vertical transportation, traction lift systems transform the means passengers move within skyscrapers (lift maintenance contractors). These systems run based on the concept of rubbing in between the lift automobile and the hoist ropes, permitting for reliable vertical motion. Traction lift systems are frequently located in modern-day skyscrapers and are recognized for their smooth adventures and energy efficiency

One common sort of traction system is the geared grip system, where the lift cars and truck is affixed to the hoist ropes with a gear system. This configuration provides outstanding control over the motion of the lift my review here cars and truck and is suitable for mid to skyscrapers. Another kind is the gearless traction system, which removes the demand for a gear system, making it more suitable and portable for extremely look at this site tall buildings.

Despite their performance, grip lift systems can experience malfunctions such as rope slippage, electric motor failures, or concerns with the control system. Normal upkeep and prompt repair services are vital to ensure the risk-free and reputable procedure of grip lift systems in skyscrapers.

Pneumatically-driven Lift Solutions

Pneumatically-driven lift systems make use of air pressure differentials to help with vertical transportation within buildings. These systems run by utilizing pressed air to move the lift auto within a hoistway. As the atmospheric pressure boosts or decreases in the system, the elevator is either raised or lowered appropriately. Among the crucial benefits of pneumatic lift systems is their power performance contrasted to traditional traction systems, as they do not require weights or comprehensive equipment.

However, pneumatic lift systems are not without their common breakdowns. Normal upkeep and monitoring of the system's air stress levels are critical to protect against these malfunctions and make certain the trustworthy procedure of pneumatically-driven lift systems.

Chairlift Solutions

In the realm of vertical transport devices, Chairlift Solutions provide a distinct alternative to the pneumatic lift systems talked about previously. Chairlift Solutions are typically used in ski resorts, entertainment parks, and various other entertainment areas to transport individuals backwards and forwards inclines or hillsides. These systems are composed of a continually moving loophole of chairs affixed to a cord that moves in a constant loophole, permitting travelers to embark and get off at designated factors along the route.

Despite their appeal, Chairlift Solutions are not without their faults. Typical breakdowns include issues with the cable, such as derailments or slippage, which can lead to operational disruptions and safety concerns. Mechanical failures in the chairs themselves, such as malfunctioning safety and security bars or seat locks, can additionally pose threats to travelers. Routine here are the findings maintenance and inspections are crucial to protect against these breakdowns and make certain the secure procedure of Chairlift Equipments. By addressing these common breakdowns promptly, drivers can maintain the performance and dependability of Chairlift Systems for the people who rely upon them for transport and entertainment.

Verdict

In conclusion, lift systems are vital for vertical transportation in numerous structures and structures. Hydraulic, traction, pneumatically-driven, and chairlift systems are typically utilized, each with their own possible malfunctions and distinct features. It is crucial for upkeep employees to be experienced about the varied ranges of lift systems and their typical breakdowns to make sure the safety and security and effectiveness of these systems.

As with any kind of mechanical system, lift systems are vulnerable to malfunctions that can vary from small hassles to essential failures.Relocating from the realm of elevator systems introduction to a more specialized domain, hydraulic lift systems offer an unique technique to upright transport within structures.One typical type of grip system is the geared traction system, where the lift cars and truck is connected to the hoist ropes via a gear system. Normal upkeep and surveillance of the system's air stress levels are critical to stop these malfunctions and make sure the dependable operation of pneumatically-driven lift systems.

It is vital for maintenance employees to be well-informed about the varied varieties of lift systems and their regular malfunctions to guarantee the security and efficiency of these systems.

Report this page